Menu

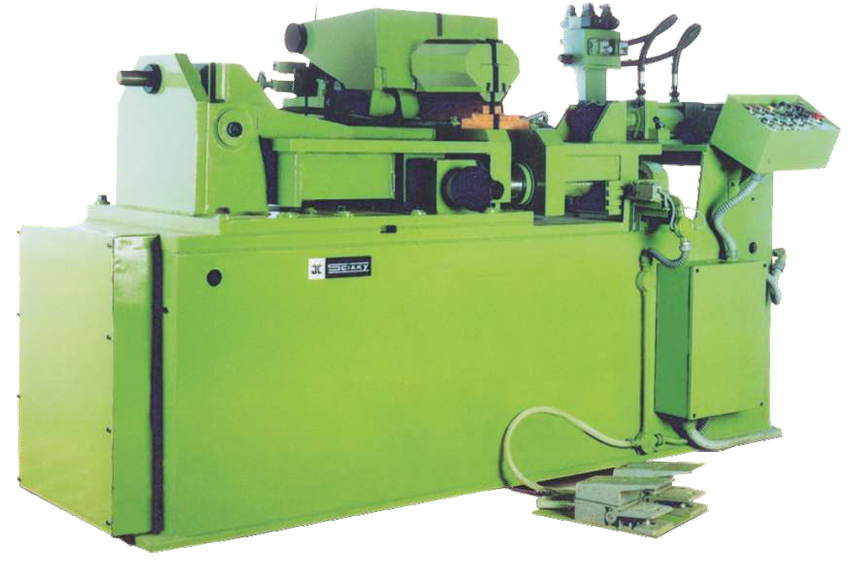

Hydraulic Flash Butt Welding Machine

Hydraulic Flash Butt Welders are designed for Heavy Duty application & High Strength Welding of joints with Large Cross Section.

Construction :

Rigid Fabricated Frame - Minimum Deflection

Encapsulated Welding Transformer - Longer Life

Low impedance Secondary Circuit - Higher Welding Capacity

Features :

Direct acting lever arm clamps with cylinders placed away from flashing zone.

Low friction, accurately aligned movement of Platen.

Hydraulic power pack for positive clamping and upsetting under high pressure.

Controller flashing through flow control.

Accurately machined toolings to match with component profile.

Automatic machine sequence control with PLC for high productivity.

Thyristor power control with tap switches on transformer for optimum weld joint strength

Applications :

Auto Components - Gear Shifter

Chain Link - Ring Gear

Tools - Steering Columns

Wheel Rims - Tractor Links

Machine Data :

| Machine Type | UNIT | FBH 100 | FBH 150 | FBH 250 |

|---|---|---|---|---|

| Rating at 50% duty cycle | KVA | 100 | 150 | 250 |

| Clamping force | kg. | 6000 | 12000 | 18000 |

| Upsetting force | kg. | 4000 | 8000 | 12000 |

| Maximum Capacity | ||||

| Low Carbon Steel (Expanded Section) | Sq.mm | 650 | 1300 | 2000 |

| Low Carbon Steel (Compact Section) | Sq.mm | 375 | 750 | 1200 |

| Medium Forging Grade Steel | Sq.mm | 320 | 650 | 1000 |

Machine Installation Data :

| Power Supply | Volts | 415 | 415 | 415 |

|---|---|---|---|---|

| Freq (Hz) | 50 | 50 | 50 | |

| Phase | 1 (2 Lines) | 1 (2 Lines) | 1 (2 Lines) | |

| Disconnect Fuse (HRC) Rating | Amps | 250 | 300 | 400 |

| Supply Cable Size Cu - 1 Core Al - 3 Core |

mm2 mm2 |

185/Line 300 |

185/Line 300 |

300/Line 400 |

| Water Supply (Pressure 3 kg/cm ) Soft Water (Inlet Temp. <300C) |

Lit /min. | 40 | 45 | 50 |

Machine Size :

| Dimensions | ||||

|---|---|---|---|---|

| Height | mm | 1500 | 1900 | 1900 |

| Width | mm | 900 | 1100 | 1100 |

| Length | mm | 1850 | 2500 | 2500 |

| Weight (approx.) | kg. | 3500 | 4000 | 4500 |